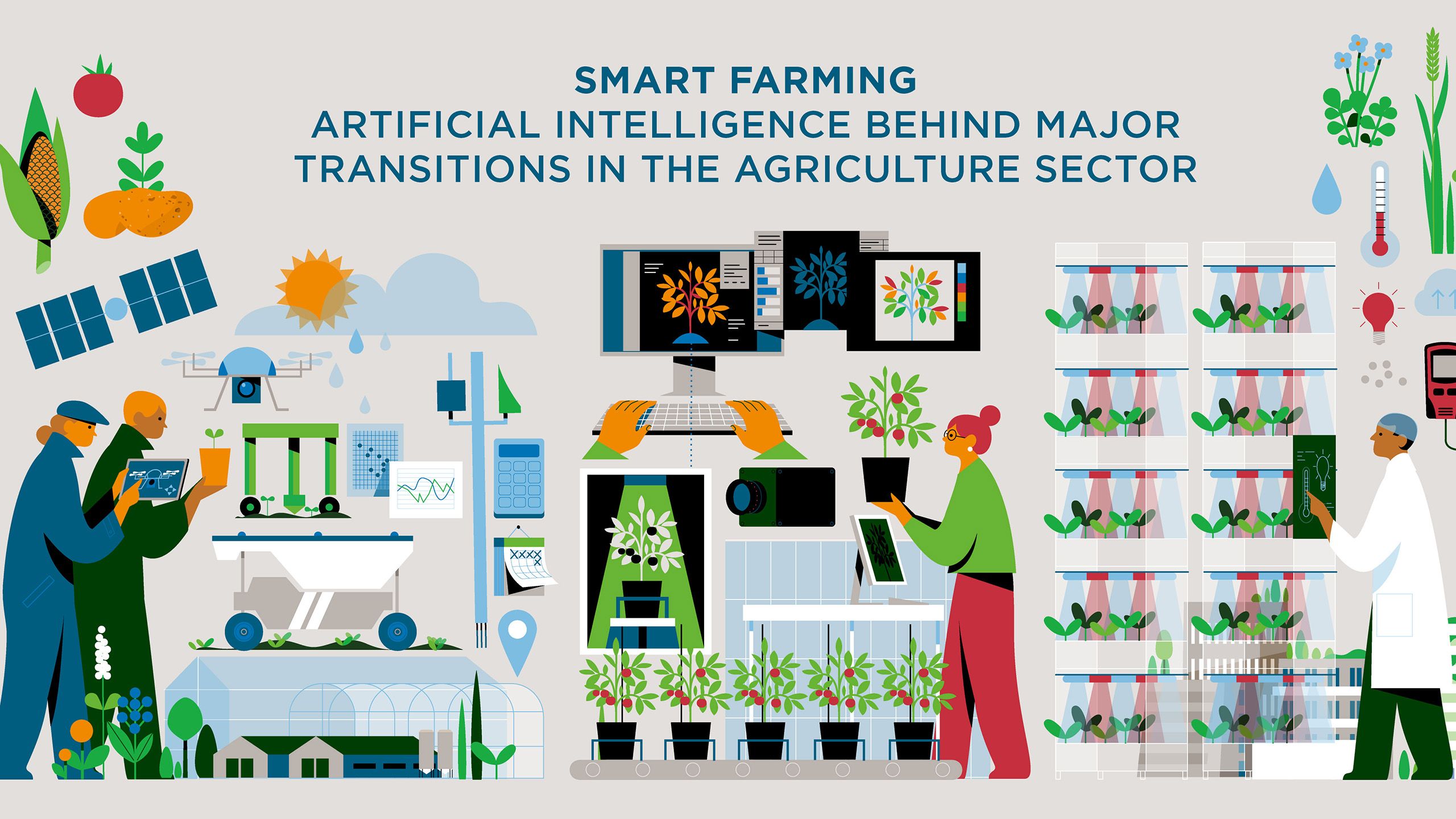

The agriculture sector is innovating fast. Today there are drones that fly over fields to measure crop growth and robots that can detect and remove weeds. Big Data and Artificial Intelligence are helping to make this sector more efficient and sustainable. But there are challenges too.

Just picture it: in a tomato greenhouse, sensors are independently monitoring the growth of the plants. The temperature is carefully managed and vents open by themselves if it gets too hot. The plants are automatically given exactly the right amount of water and fertiliser. A robot measures the size, quantity and ripeness of the tomatoes, and monitors photosynthesis and evaporation. This may sound like the farm of the future, but in fact farmers, horticulturists and researchers are already pioneering with autonomous production systems. They need to meet the major challenges the agriculture and horticulture sector is facing.

By 2050, the world’s population is expected to have reached almost 10 billion. The demand for food is rising. At the same time, climate change will make farming more difficult, making it all the more urgent to switch to innovative methods. Researchers, farmers and horticulturists are increasingly looking to Artificial Intelligence–the ability of machines to learn, reason and make decisions based on data and algorithms–for solutions. AI helps farmers and gardeners make complex decisions so they can produce fruit and vegetables closer to their customers, more sustainably and using fewer resources.

The list of applications is virtually endless. Rick van de Zedde, program manager Autonomous Cultivation & CTO NPEC at Wageningen University & Research (WUR), gives drones, soil sensors and satellites that collect data on crops, soil, weather, pests and diseases as examples. “AI algorithms analyse these data and allow the farmer or horticulturist to make better informed decisions. They can accurately chart crop growth and determine exactly how much water, fertiliser or plant protection products are needed per square metre, or even per plant,” he explains.

The ‘digital twins principle’ can be used to predict the growth of a crop. A digital twin simulates a farm or a crop in a greenhouse as precisely as possible in a virtual world, based on real-time sensor data it receives from its physical twin. All the analysis data from the field or greenhouse, such as the soil moisture content, are shared with the computer and help to further improve the underlying greenhouse and crop growth model. Horticulturists can use this information to calculate various scenarios or cultivation strategies that will enable them to achieve higher yields with more efficient use of energy, water and nutrients. The model calculates how growers can achieve optimal results, taking into account specific conditions such as weather and crop development.

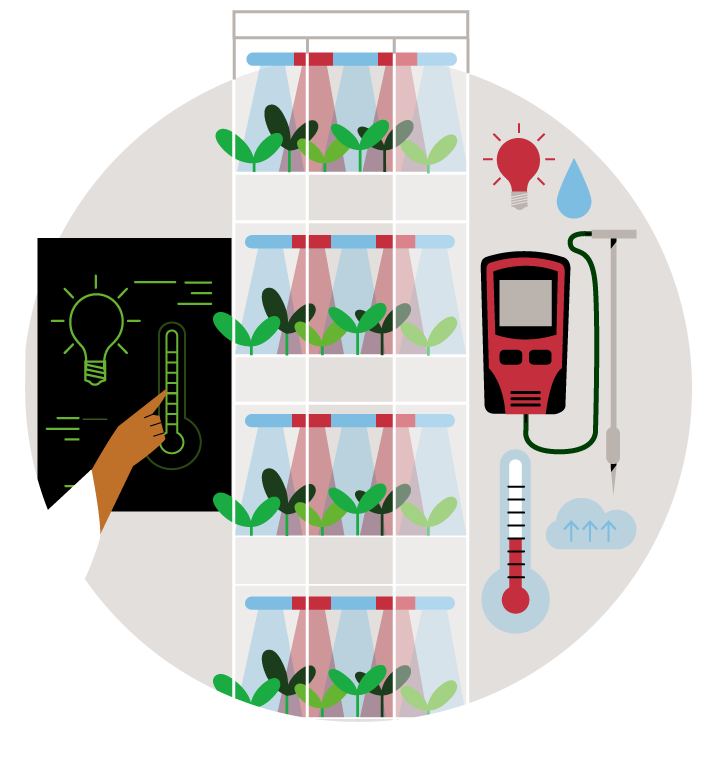

Another application of AI is in vertical farming, a new method of growing fruit and vegetables in optimised growing conditions. The crops grow in multiple vertical layers. The farmers of the future could even use vacant properties in the city for vertical farms. AI automatically adjusts the light, temperature, CO2, humidity, water and fertilisers based on the plant’s needs and using as few natural resources as possible.

The use of data and AI in agriculture is not without its challenges. For example, it is expensive to implement and farmers/growers have to be trained before they can use it. “Larger companies can invest in new technologies more easily than smaller companies,” says Van de Zedde, “and farmers and growers are still wary of adopting new technology like robotisation. But there are now enough proofs of principle that robots and drones work. Because these technologies only start generating money after some years, all the partners in the production chain and the government need to take a good look at the revenue model. In addition, experts need to train farmers and horticulturists in the use of AI technologies so they can get the most out of them.”

To make use of the broad range of possibilities AI has to offer in order to enhance food security, decrease the consequences of climate change and biodiversity loss, WUR has founded an AI Chair group. “AI offers great opportunities, and it is up to us as humans to decide how best to exploit them,” says group chair holder Professor Ioannis Athanasiadis. Read more about the group's vision on AI here.

1. Precision Agriculture

A robot drives through an onion field removing weeds and saving the farmer a lot of work. With more time on their hands, the farmer inspects the crops and determines whether irrigation is necessary using an app. On another farm down the road, soil sensors on the tractor and drones determine the precise location for spraying plant protection products on a fruit crop. The precision sprayer does its work autonomously based on a computer-generated job card.

The National Field Lab for Precision Agriculture (NPPL) project helps farmers apply these precision-farming techniques. “Precision agriculture enables farmers to decide what treatment their plants need based on more accurate information, even down to the square metre,” explains Paul van Zoggel , project manager at the NPPL. “Farmers are supervised by experts from WUR at the fieldlab so they can optimise their production process and make it more sustainable, with less use of plant protection products, fertilisers and water.”

It is possible to represent precision agriculture in a cycle: farmers/growers use techniques to measure how the crop and soil are doing. Based on these measurements, they do calculations and make decisions that benefit the crop or soil. They carry these out, and then evaluate how the crop is doing. Then, the cycle starts all over again.

Farmers/growers start by collecting data from the field or greenhouse. For this, they can use different kind of measuring equipment, such as sensors, drones and satellites. Measurements are made at time intervals and are forwarded to the computer.

On the dashboard on the computer, farmers/growers can view the data and analyse them. Based on the analysis, they can select the best option(s) to take care of their crops and soil in an optimal way.

With different precision agriculture tools, they can sow, take care of, and harvest their crops in the most optimal way.

Next, they evaluate their decisions. Did their choices give them the best result (i.e., healthier crops, more yield, etc.)? If so, they continue. If not, they adeptly execute their strategy, and the cycle begins again.

The farmers deploy various technologies to this end. Sensors monitor the crops and/or the soil, and special software uses decision rules to determine the condition of the crop or soil based on the sensor readings. The software then decides whether and what site-specific treatment is advised.

The first successes have already been achieved. For example, variable nitrogen fertilisation ensures better crop growth in potato crops and a much lower risk of run-off, resulting in cleaner water. Despite the benefits, by no means all farmers have turned to these precision agriculture models, says Van Zoggel. “Farmers receive very little compensation for adopting precision agriculture, so the efforts sometimes outweigh the benefits. Moreover, the measurements, models and management do not always interact efficiently.”

Researchers from WUR and Aarhus University have written a handbook on the potential of precision agriculture techniques and their use in practice. The handbook, Precision Agriculture: Modelling, provides an overview of the models behind precision agriculture techniques. It gives farmers and researchers an idea of current and future opportunities and challenges for precision agriculture. “For example, we noticed that farmers wanted more advice on how to deal with phytophthora, a disease that kills potatoes,” says Van Zoggel. “In the book, two phytophthora models produced by WUR and the agri-ICT company DACOM are discussed, both of which are already being used by farmers.”

According to Van Zoggel, besides more efficient interactivity between the measurements, models and management, another challenge is that farmers are not making the most of their own data. To improve this situation, WUR, BO Akkerbouw (an arable farming knowledge centre), the Ministry of Agriculture, Nature and Food Quality and the Netherlands Enterprise Agency jointly launched a data sharing roadmap: ‘Towards a data ecosystem for the arable sector’. Central to this approach is a ‘data room’ for each farmer where they can manage and analyse their own data. The farmer can use this data as a basis for decision-making on their farm and control how their data is shared with other farmers and experts.

The illustrations in the above part of the article are made by Steffie Padmos.

|

FarmMaps and the Farm of the Future External parties can offer precision agriculture services on FarmMaps (www.farmmaps.net). This is an open data-service platform for agricultural research and education and production cycle optimisation. Stichting Akkerweb (whose board comprises WUR staff) developed and operates the platform. FarmMaps collects all the relevant data and offers additional services to support the development, testing and implementation of new applications (apps). There are currently more than 20 apps developed by WUR and external parties that make use of FarmMaps data to provide insights and advice on growing more sustainable crops. Interested parties can also check out Farm of the Future . On this website, WUR researchers and farmers reveal how you can use data and technology to make farming easier and more efficient and reduce inputs on arable farms. Farm of the Future: It is closer than you think. |

2. Digital Twins

Tomato digital twins

WUR researchers are trying to predict the future of a tomato crop. In the high-tech research greenhouse of the Netherlands Plant Eco-phenotyping Centre, they are working on a virtual crop (computer model) that precisely reveals how plants grow under different conditions. The virtual crop is the ‘digital twin’ of the physical crop in the greenhouse. The results of the research will soon enable horticulturists to use water, nutrients and energy much more efficiently.

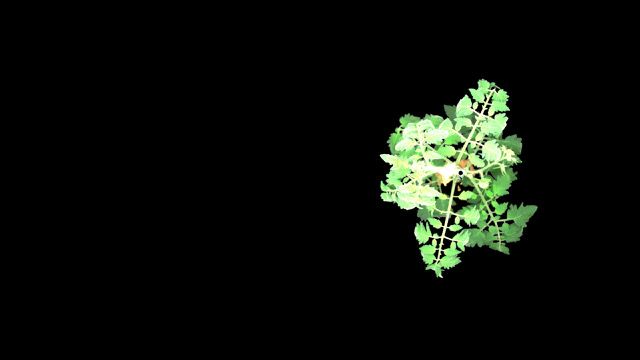

Tomato plants are lined up neatly on a conveyor system, each in their own pot. One by one they pass through a monitoring station on the side of the greenhouse. Cameras and sensors measure dozens of characteristics of the plant and its environment, from the plant’s architecture and the water content of the fruit, to the maximum amount of light a plant can absorb. This is more complicated with larger plants and fruits, so here the sensor-to-plant principle is used (the monitoring system in the greenhouse rides to the plants instead).

“We mimic the plants as precisely as possible based on various data from the greenhouse,” says senior researcher Pieter de Visser . “We simulate the interaction between the various crop characteristics, environmental factors and crop management practices in the virtual crop and so learn how the different plants respond to changes. The digital twin can also calculate hypothetical scenarios, such as the effect of using less water, or alternative greenhouse glazing with more optimised light incidence. So a horticulturist can make better choices for their physical crops based on the results of the digital twin.”

Among others, hyperspectral and 3D cameras are used to collect the data. They use AI models for analysis and image processing. The sensors feed real-time data to the computer model, such as the daily weight measurements. The advantage of this is that the model can first analyse the effect of management decisions on the virtual crop and project these to the practical situation.

The system constantly checks whether the digital twin accurately reflects the physical crop and adjusts the model where necessary. This all happens while the real crop is growing and developing. Horticulturists can also apply the digital twin principle to automatically control the climate in the greenhouse. Or it could be used to analyse research into pruning strategies, test different types of greenhouse roof covers, or select for the best crop traits, for example. In addition to the trial with tomato plants, WUR is also investigating the added value of digital twins for the cultivation of cucumbers and chrysanthemums.

On the right, you can see three examples of data produced by the different measuring cameras of NPEC.

3. Vertical Farming

Vertical farming: growing vegetables in the city

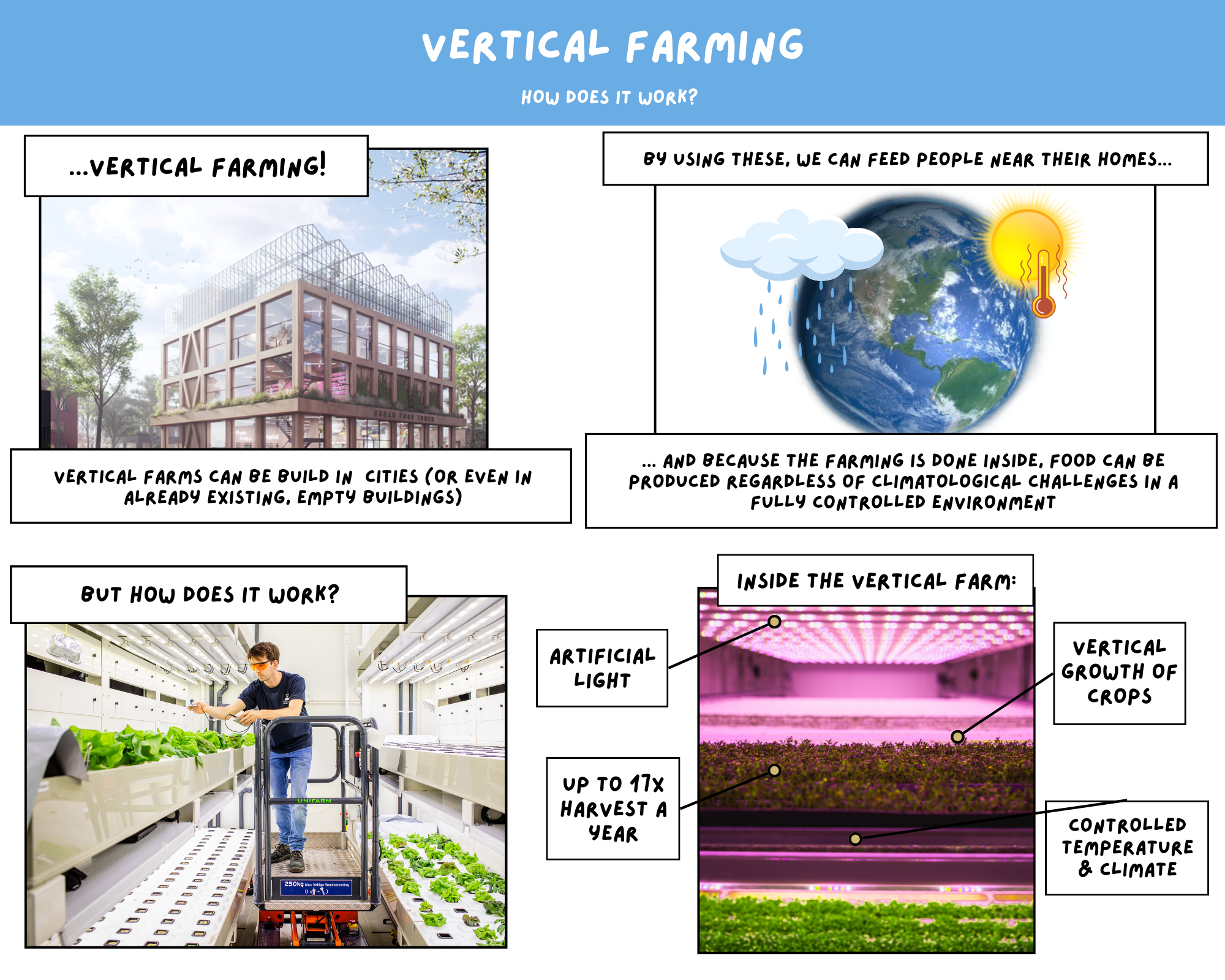

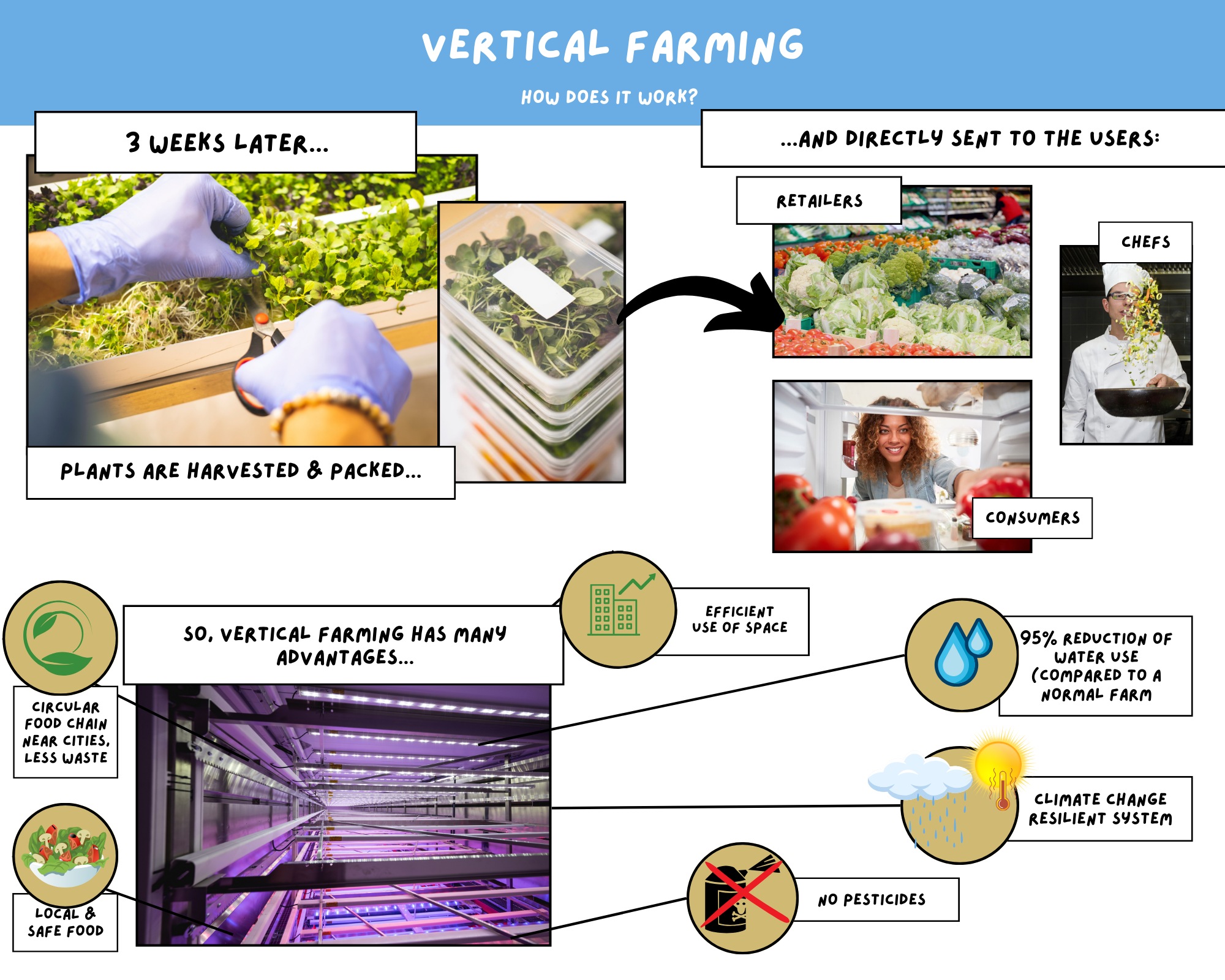

Vertical farming could revolutionise fresh vegetable production. Developing farms in buildings in cities is a safe, healthy and sustainable way to feed their growing populations with locally produced fruit and vegetables. Vertical farms are suited to all urban areas and climates, be it very hot, very cold, or very dry, even if there is no fertile soil available. The only disadvantage is the high energy consumption and high investment costs. WUR is participating in several vertical farming studies to find solutions to these problems.

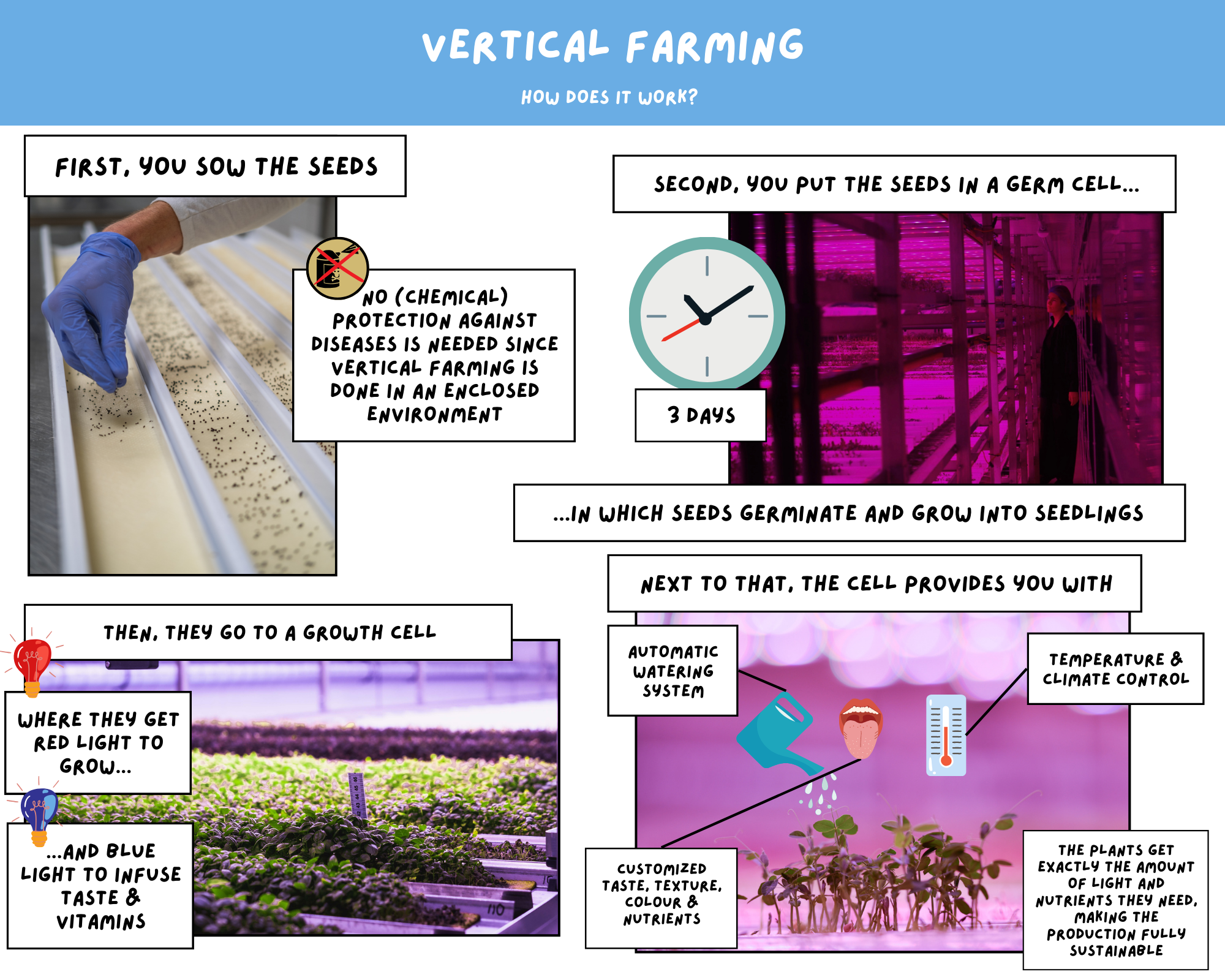

Vertical farming is a system for growing crops indoors in a fully climate-controlled environment with LED lights. Farmers, horticulturists and researchers grow the crops on vertically stacked plateaus, enabling them to make optimum use of the relatively small available area. Vertical crops grow without pesticides and need only 2-4 litres of water per kilogram of vegetables on a 10-20 times smaller area of land.

In Amsterdam, the company Growy has developed an efficient, fully automated and AI-powered vertical farm that grows Brussels sprouts and herbs. Growy’s employees can optimally adjust the conditions for the plants based on sensor data on the plant’s weight and CO2, light, air and moisture levels. Head of the Horticulture and Product Physiology Chair Group at WUR, Leo Marcelis: “In a vertical farm employees know exactly how many nutrients and how much water the plants need. By controlling the crops so closely, they are able to grow healthy Brussels sprouts and herbs with a long shelf life. You can also use such data-driven systems to adapt the crops to meet specific requirements, for example for colour, flavour, structure or nutritional elements, and so produce a tailor-made food product.”

Although vertical farming requires much less water and no pesticides, the energy consumption required to achieve optimum climate conditions is still a challenge. Researchers have not yet fine-tuned vertical farming systems at the microlevel to provide the ideal amount of light, heat and air to specific crops. The systems still consume a huge amount of energy, so improving energy efficiency is a major focus of research at WUR. Recently, researchers discovered that choosing a variable lighting plan can save a lot of energy and can even improve the health of the plants. Read more about it here.

The Bleiswijk research site of WUR’s Glasshouse Horticulture & Flower Bulbs Business Unit also has a dedicated vertical farming unit, where researchers are studying how to efficiently grow fruit and vegetables in controlled conditions. The researchers can also simulate regional climate conditions in their laboratories. Farmers and horticulturists can use the data to optimise the conditions for specific crops.